Optional command thc interface – Hypertherm HPR260 Auto Gas Preventive Maintenance Program Rev.5 Manual del usuario

Página 230

4

3

2

1

1

A

4

3

2

A

B

C

D

B

C

D

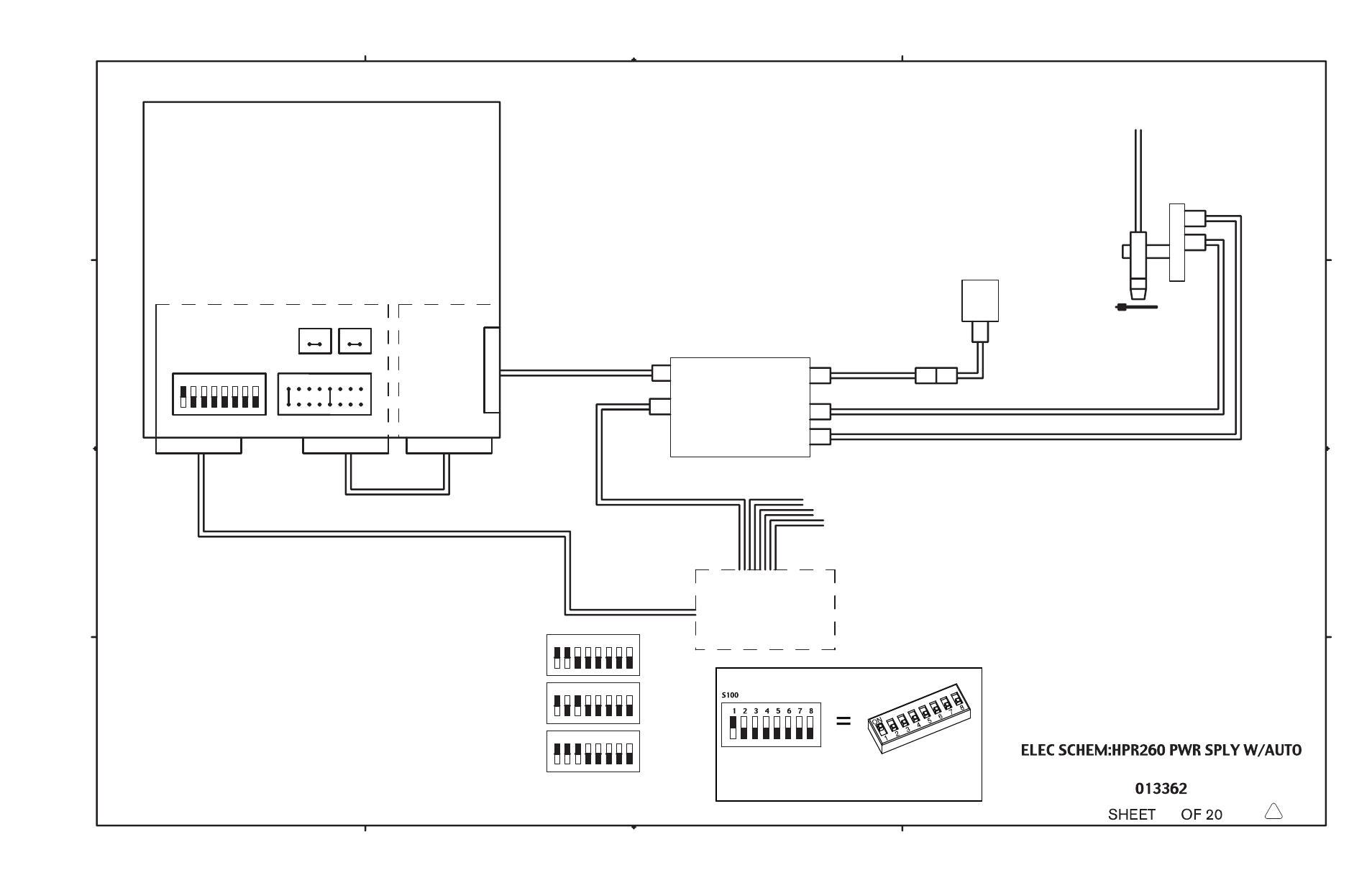

Interface

CNC

(Customer Supplied)

041909

CONTROL BOARD

S100

1 2

J303

3 4

3

2

1

4

J300A

J300B

CNC Interface Cable

Workpiece

CNC Interface Cable

(Optional Unit)

THC

Command

CNC Interface Cable

Pendant Ext. Cable

(Optional Unit)

Operator

Pendant

Lifter

Torch

(Optional Unit)

Motor Drive Cable

Lifter I/O Interface Cable

J2B

J2A

PLASMA INTERFACE BD

041842

Serial ID

Dipswitch

Jumper Block

Machine Motion

CNC Interface Cable

Command I/O Cable-Second THC

Command I/O Cable-Third THC

Command I/O Cable-Fourth THC

Serial ID

S100

S100

Serial ID

S100

Serial ID

1 2

J106

1 2

J107

Optional Command THC Interface

1

3

2

4

1 2 3 4

1 2 3 4

1 2 3 4

5 6 7 8

5

7

6

8

5

7

6

8

6

5

8

7

Torch

Notes:

1) For a single system installation set Serial ID (S100),

Machine Motion (J303), J106 & J107 as shown

2) For a two system installation duplicate a second power supply and Command THC

as illustrated for a single system, set Serial ID as shown for the second system

3) For a three system installation set up as described above, set Serial ID as shown

for the third system

4) For a four system installation set up as described above, set Serial ID as shown

for the fourth system

5) All machine interface cables (Pwr. supply-CNC) used for serial communication between

Pwr. supply-CNC will have a common connection node with the CNC

6) The CNC will need a dedicated I/O port for each Command THC

HPR PAC

Dry Cutting System

D

20

See Command THC

Manual for internal

Power Supply wiring

Dipswitch

(2 systems)

Dipswitch

(3 systems)

Dipswitch

(4 systems)

7-26

5

Dipswitch setting example:

Switch 1 is in the ON position.

Switches 2-8 are in the OFF position.

*

*

* If a Hypertherm Automation controler is being used, and there are intermittent

communication failures (PS Link Failure), try removing the jumpers on J106 and J107

on the control board, and the termination jumper (J6 or J8) on the serial isolation board

in the controler. Only remove the termination jumper on the serial isolation board that

is connected to the HPR power supply. See sheet 19 of 20 for more details.